SURFACE TREATMENT

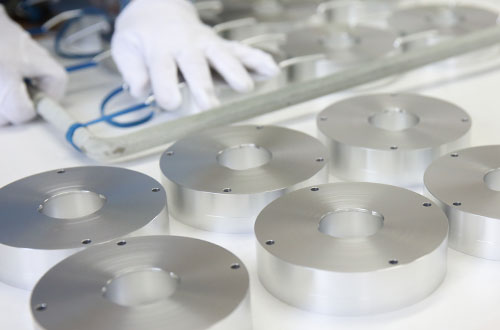

Anodic oxidation process (alumite)

Anodic oxidation process (alumite)

What is anodic oxidation process (alumite)?

It is a process which forms an aluminum oxide film (artificial oxide film) on the surface by soaking aluminum in a chemical solution and running current so that it functions as an anode (+ pole). It is also called anodic oxidation process.

Black alumite

Characteristics

- It improves the corrosion resistance.

- It can harden the material, and improves the abrasion resistance.

- Due to the film having honeycomb-like structure, it can be colored in various different colors by impregnating dye pigments in the fine holes.

White alumite(Color of the base material)

Cautionary notes, etc.

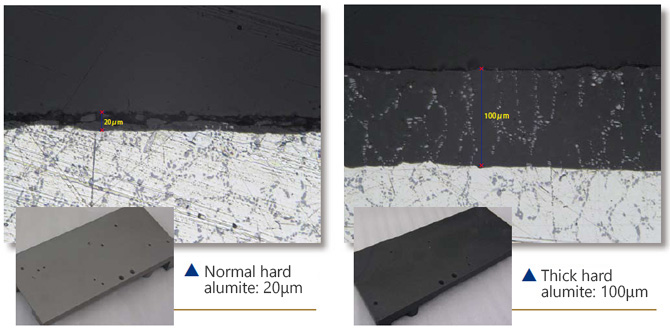

Since the film grows while dissolving the material itself, caution is required on products with small dimensional tolerances. In principle, about 1/2 of the alumite film thickness grows outward while the other 1/2 grows and permeates inward. Therefore, the outer diameter increases by about 1/2 of the film thickness from the dimension before treatment. In addition, the alumite film may become colored depending on the type of aluminum material. Hard alumite with large film thickness in particular varies in color by the business providing treatment.

Thick hard alumite on cast metals

We can provide thick hard alumite treatment up to film thickness 30 to 100μm on cast metals, while the conventional hard alumite treatment on aluminum castings comprises 15 to 30μm.