SURFACE TREATMENT

Electroless nickel plating

Electroless nickel plating

Plating can be performed uniformly regardless of the shape of the product!!

Treatment is possible for small to large and long-length (3m) objects, and objects up to 3 tons in weight.

Lead-free plating is also available.

What is electroless nickel plating?

Like nickel electroplating, electroless nickel plating forms an alloy with phosphorus and a film which is mainly comprised of nickel. If the purpose is rust prevention, there is little difference between the two methods. However, electroless nickel covers the entire product with the film regardless of its shape and thus excels nickel electroplating in corrosion resistance as a result.

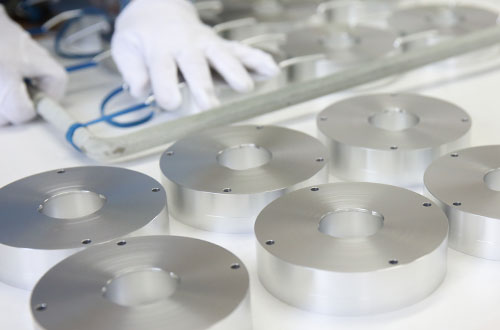

Plated products with complex

shapes of size approximately 10mm

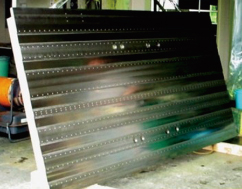

A large plated product approximately

the size of an adult's height

Difference by functions

When functions are the purpose of plating, it is possible to increase the hardness of the material by adding thermal treatment to electroless nickel plating. On the other hand, nickel electroplating is better than electroless nickel plating if luster in appearance or low electric resistance is required. The differences in film characteristics are listed on the table below.

Electroless nickel plating on aluminum material

Comparison between electroless nickel plating and nickel electroplating

| Electroless nickel | nickel electroplating(Luster) | ||

|---|---|---|---|

| Film characteristic | Components | Ni90~92% P8~10% |

Ni99.5% |

| Melting point | 890℃ | 1450℃ | |

| Electric resistance | 60μΩ/cm | 8.5μΩ/cm | |

| Specific gravity | 7.9 | 7.7 | |

| Hardness (Hv) | 500±50 (750 or higher with thermal treatment) |

450±50 | |

| Abrasion resistance | 13.7 | 14.7 | |

| Elongation | 3%~6% | 5%~15% | |

| Stress | Compressive | Tensile | |

| Magnetism | Non-magnetic | Magnetic | |

| Precipitation properties | Stable uniformity | Unstable uniformity | |

| Advantages | ・Uniform plating is possible even on products with complex shapes. ・Hardness can be increased. |

・Luster is present. | |

| Disadvantages | ・Luster is lower than that of nickel electroplating. | ・Plating varies on products with complex shapes. ・ Not resistant to heat. |

|

Electroless nickel PTFE

Electroless nickel PTFE is an electroless nickel plating process in which nickel goes through eutectoid reaction with fine particles of polytetrafluoroethylene (PTFE).

Its film has excellent properties in lubrication, water repellency, abrasion resistance, and non-adhesiveness. In addition, the characteristics of electroless plating allow formation of a uniform plating film even on products with complex shapes.

It supports not only alloys but also cast metals and die cast.Treatment is also possible on other materials, including copper and stainless steel.

Standard characteristics

| Physical properties | ||

|---|---|---|

| Nickel (Ni) | 81 ~ 86wt% | |

| Phosphorus (P) | 8 ~ 11wt% | |

| Fluororesin (PTFE) | 4 ~ 9wt% | |

| Density | 6.3 ~ 7.1g/㎝3 | |

| Hardness | After plating | Hv300 ~ 450 |

| After thermal treatment (300℃) | Hv450 ~ 600 | |

| Electric resistance | 150 ~ 250μΩ・㎝ | |

Friction coefficient

The friction coefficient is smaller as the content of PTFE is larger, and excellent self-lubrication is addressed by adding thermal treatment which melts and deforms the PTFE particles (at around 350℃) to further shrink in size.

Water/oil repellency

The contact angle to the water is large in a similar fashion to Teflon coating, which makes the material resistant to becoming wet and non-adhesive.

It therefore excels in release characteristics and detachability.

Adhesion

Each of the PTFE particles is retained rigidly by the matrix.

Since this matrix is a metal, adhesion with the base material is quite strong.

Abrasion resistance, damage tolerance

PTFE film surface is resistant to scratches and does not easily peel off.